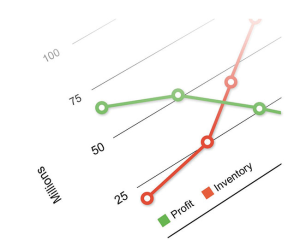

Spare parts cost companies millions of dollars each year. In truth, this multimillion-dollar section of the balance sheet is often overlooked. Companies may avoid strategies to improve their MRO spare parts materials because they may not be as “sexy” as strategies for finished goods.

Because of this, companies are severely overinvested in spare parts. Failure to realize their strategic importance leads firms to experience incorrect inventory levels and inflated annual spend, directly impacting working capital and profitability as well as operational performance.

It’s important to recognize that companies experience a higher and more immediate hard dollar return from implementing MRO strategies, whereas results from MRO strategic initiatives go directly to the bottom line.

The question becomes, “Who owns this strategy and who in the organization should be held accountable for making it happen?”

As many company leaders discover, various audit points have exposed MRO material issues throughout the enterprise, creating a very large pain point especially for the CFO and Plant Controllers. Lack of any strategy leads to Sarbanes-Oxley (SOX) exposure, significant expenditure in avoidable costs, and reduced operational efficiencies:

- Poor identification of MRO materials causes unnecessary higher annual spend, typically in the range of 16% to 23%.

- Incorrect order points, lead times, and order quantities cause inventory levels to be inflated, with levels growing 6.7% per year.

- MRO stock with values in the millions of dollars is unaccounted for throughout a plant (a major SOX issue).

- Unnecessary purchases are made each year due to poor inventory identification, which also results in unnecessary expedited shipping costs.

- 25% of maintenance time is wasted looking for the right part.

- Opportunities are missed to control other measurable financial and operational factors that could be eliminated with the proper oversight and strategies in place.

In 12 months or less, based on the enterprise’s size, a complete and optimized strategy for MRO can be implemented to deliver bottom line, multimillion-dollar savings. Returns on project investment often exceed 30%. A return of this size is significantly higher than any company’s cost of capital. Furthermore, it can all be accomplished while improving operational effectiveness and production up-time, making sure you remain a competitively low-cost operation.

MRO strategic initiatives must be developed as a comprehensive plan, but most importantly, they must be driven as a team effort by upper and middle management. This will ensure the initiatives undertaken are comprehensive, logical to implement, and sustainable. This approach will also confer accountability to a select few within the organization, typically in partnership with finance and operations.

Approaches to consider in your strategic plan include:

- Creating a comprehensive plan to deliver targeted MRO solutions that use industry-specific knowledge, encompasses a well-developed project plan along with critical measurable KPIs, and ensures optimal implementation with input from all stakeholders.

- Where necessary, cleansing and standardizing item descriptions across the enterprise item master to correct years of erroneous, obsolete and duplicate data. This will eliminate unnecessary inventory and leverage better information to reduce annual spend. It will also improve time spent by maintenance personnel.

- Implementing an ongoing data governance model to ensure data quality is sustained once the cleansing and standardization is complete to avoid corrupting the data again.

- Disposing of irrelevant inventory efficiently to recoup a high percentage of past capital investments.

- Creating perfect storerooms throughout the enterprise using industry best practices that optimize physical space and storeroom operating procedures.

Results expected from implementing this approach include but are not limited to:

- Reduced working capital funding requirements

- Lowered annual spend on inventory

- Reduced downtime by having the right part, at the right time, with the right quantity

- Strengthened controls to account for all inventory values

- Eliminating false stock out costs

- Significantly reduced shipping costs from greatly reduced emergency orders

As you may realize, these approaches impact many areas within an organization. This is why any MRO strategic plan must have the right ownership to be fully effective.

Asset-intensive companies that employ MRO strategies specific to their needs and processes are realizing these benefits quickly, making them increasingly competitive in their industry.

We have seen various organizational arrangements to ensure MRO strategy ownership not only has prominence within the organization but also is supported from the “C” suite, especially the CFO and COO/EVP of Operations.

Developing the comprehensive plan mentioned earlier provides the roadmap for upper and middle management to understand, buy into, and manage the strategy properly and efficiently. Depending on the culture of the organization, accountability for overseeing and implementing the strategy can be accomplished either through a steering team or by appointing one person to be the MRO strategy czar. Either way, the approved and often fluid roadmap must be created and monitored to ensure results are being realized in a timely and efficient manner.